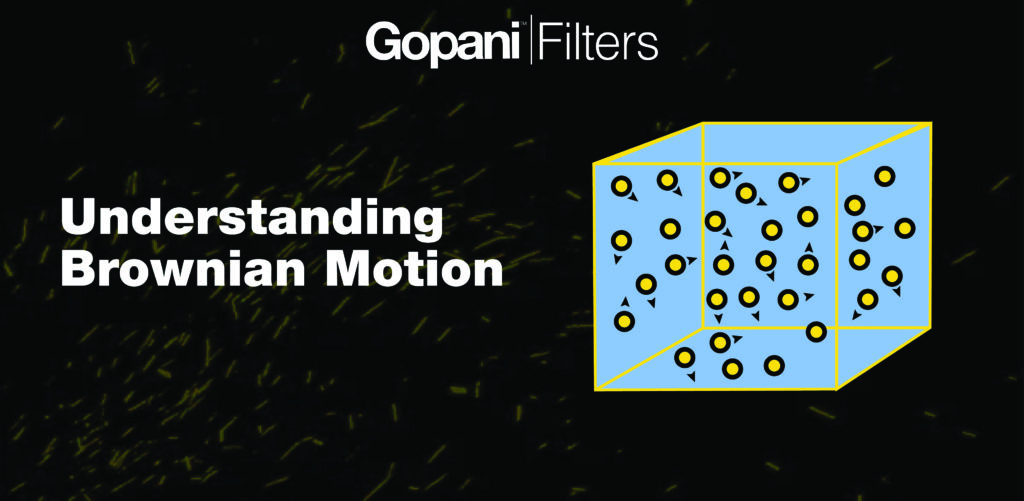

Brownian motion, the random movement of particles in a fluid, has fascinated scientists since Robert Brown’s 1827 discovery. This phenomenon, essential in fields like physics and biology, varies significantly depending on the medium in which it occurs. In this article, we explore how Brownian motion behaves differently in compressed air and steam, both at seven bar pressure.

Factors Influencing Brownian Motion:

- Density : Denser media result in more frequent collisions between molecules and suspended particles.

- Viscosity : Higher viscosity can dampen particle movement, reducing the intensity of Brownian motion.

- Temperature : Increased temperature boosts molecular kinetic energy, intensifying particle collisions.

- Molecular Mass : Lighter molecules move faster, leading to more frequent and energetic collisions.

Compressed Air at Seven Bar:

Compressed air, primarily composed of nitrogen and oxygen, becomes denser under pressure, leading to more molecular collisions. Although its viscosity increases, it remains lower than that of liquids, slightly dampening particle motion.

Steam at Seven Bar:

Steam, the gaseous form of water, has lower density and viscosity compared to compressed air. This allows particles to move more freely, and because water molecules are lighter, they collide with particles more energetically, potentially increasing the intensity of Brownian motion.

Kinetic Theory and Brownian Motion:

The kinetic theory explains that gas molecules are in constant motion, and their speed increases with temperature. In compressed air, heavier molecules move more slowly, resulting in less energetic collisions. In contrast, steam’s lighter molecules move faster, causing more intense particle collisions.

Comparative Analysis:

While compressed air’s higher density leads to more frequent collisions, steam’s faster molecular movement and lower viscosity likely result in more intense Brownian motion. Thus, steam at seven bar may exhibit stronger Brownian motion compared to compressed air under the same conditions.

Applications:

Understanding how Brownian motion varies across different gases is vital in fields like aerosol technology, environmental science, and industrial processes. For instance, it impacts the effectiveness of inhalers, the dispersion of pollutants, and the efficiency of gas filtration systems.

Conclusion:

Brownian motion remains a fundamental concept with broad implications across science and industry. By comparing its behavior in different gases like compressed air and steam, we gain valuable insights that help refine technologies and processes across multiple fields.

Filtration Efficiency

The efficiency values below are given for air and water at a given flow rate.

Types of Sintered Filter Elements

Factors to Consider before Buying a Sintered Cartridge Filter

- Operating conditions (temperature, pressure and flow rate)

- Filtration precision and filtration efficiency

- Appropriate material (corrosion resistance and high temperature resistance)

- Allowable pressure drop

- Appropriate medium strength (tensile strength, fatigue strength and load capacity)

Sintered Filter Elements and Systems for Tailored for Industries Like

Pharmaceuticals and API

Speciality Chemicals

Food and Beverage

Transportation

Refining and Petrochemicals

Fine Chemical

Instrumentation

Diagnostics

Have Questions About Our Product ?

Drop in your Requirement Details

Talk to our representative to get insight on which product will suit you.

Related Blogs