Gopani Filters is India’s only manufacturer of sintered metal filters. With the latest technology and modern facilities, they are known for producing high-quality filters. We will discuss Gopani Filters’ product range, industry expertise, and OEM offerings in this blog.

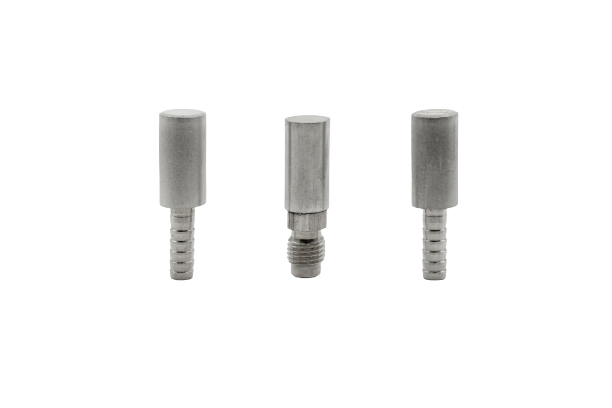

Sintered Metal Filters are widely used in various industries for their high filtration efficiency and durability. These filters are made by sintering metal particles together, which creates a porous structure that allows fluids or gases to pass through while trapping unwanted particles or impurities. Gopani Filters offers a wide range of sintered metal filters with different materials, sizes, and shapes, to cater to various applications.

One of the key strengths of Gopani Filters is their expertise in providing customized solutions to their customers. They work closely with their customers to understand their requirements and provide them with tailor-made filters that meet their specific needs.

Gopani Filters has a strong presence in several industries, including the pharmaceutical, food and beverage, chemical, and oil and gas sectors. We have in-depth knowledge of the filtration needs of these industries and offer solutions that are tailored to their unique requirements. For example, in the pharmaceutical industry, We offer filters that meet the strict regulatory standards, such as USP Class VI and FDA compliance, while in the food and beverage industry, we provide filters that are safe for human consumption and do not affect the taste or quality of the product.

In addition to their standard metal filter product range, Gopani Filters also provides OEM (Original Equipment Manufacturer) Type offerings, where they work with equipment manufacturers to develop filters that are integrated into their machines or systems. This allows manufacturers to provide their customers with complete solutions that are reliable, efficient, and of high quality.

In conclusion, Gopani, As the only company in India manufacturing sintered metal filters , catering to various industries with their wide range of products and customized solutions. Their expertise in the industry, combined with their commitment to quality and innovation, has made them a trusted partner for many customers.

You can contact us at sales@gopani.com or call us at +91 706 901 8060 to know more about your filtration need.

sintered metal mesh, sintered metal plate, sintered metal powder filter, sintered metal powder filters, Sintered metal powders, sintered metal sparger, sintered metal sparger for fermentation, sintered metal spargers, sintered metal tube, sintered muffler, sintered nickel filter, Sintered Parts Manufacturer, sintered plate filters, sintered porous metal, sintered porous metal filter, sintered porous metal filter elements, Sintered porous metal spargers, sintered porous metal tube, sintered porous powder metal filter cartridges, sintered porous stainless steel filters, sintered porous tubes, sintered powder filter, sintered powder filter cartridge, sintered powder filters, sintered powder metal, Sintered Powder Metal Filter Cartridge

Standards

ISO 12500-3 in gas = Air and ASTM F795 in Liquid = Water

Types of Sintered Filter Elements

Sintered Powder Metal Filters, sintered powder metal ultrafine tubes, sintered powder porous metal spargers, Sintered PTFE Filter, sintered sparger, Sintered Sparger Exporter, sintered sparger manufacturer, Sintered Sparger Supplier, Sintered Spargers, sintered ss filter, sintered ss filter cartridges, sintered ss filters, sintered stainless, sintered stainless filter, sintered stainless steel, sintered stainless steel filter, sintered stainless steel filter disc, sintered stainless steel filter tube, sintered stainless steel filters, sintered stainless steel tube, sintered steel filter, sintered titanium filter, sintered tube, sintered tubular, Sintered Wire Mesh Filter

Factors to Consider before Buying a Sintered Cartridge Filter

- Operating conditions (temperature, pressure and flow rate)

- Filtration precision and filtration efficiency

- Appropriate material (corrosion resistance and high temperature resistance)

- Allowable pressure drop

- Appropriate medium strength (tensile strength, fatigue strength and load capacity)

Sintered Filter Elements and Systems for Tailored for Industries Like

Pharmaceuticals and API

Speciality Chemicals

Food and Beverage

Transportation

Refining and Petrochemicals

Fine Chemical

Instrumentation

Diagnostics

stainless steel porous, stainless steel powder sintered filter, Stainless Steel Round Tube, stainless steel sintered filter, Stainless Steel Sintered Filter Cartridge, stainless steel sintered mesh, Stainless Steel Sintered Metal Filter, Stainless steel sintered porous sprayer, stainless steel sintering temperature, stainless steel sparger, Stainless Steel Tube, stainless steel wire mesh filters, static in line mixer, static mixer datasheet, static mixer element, steam filters, steam filters for sterilizers, steam filtration, steam line filter, steam purifier, steam sparger, steam sparger design, steam sparger design calculation, steam sterilization, stone bubbles, tablet dissolution test column filter, tank sparger, thermacore heat pipes, Tube Shape Spargers, types of sparger in fermenter, Ultra high-purity sintered gas filters, what is airstone, what is culinary steam, wick in heat pipe, wine carbonation

Have Questions About Our Product ?

Drop in your Requirement Details

Talk to our representative to get insight on which product will suit you.

Related Blogs