Sintered Stainless Steel Filters from Gopani: Benefits for Industrial Liquid and Gas Filtration

Written by dharmagnagopanigmail-com

Industrial filtration peripherally impacts liquid and gas quality assurance for various sectors. Advancements urge more effective, reliable and enduring solutions. Sintered stainless steel filters, an innovation with indigenous technology by Gopani, hold considerable promise for industrial filtration’s future. This post will explore why sintered stainless steel filters are becoming the preferred choice for industrial applications.

Sintered SS filters offer exceptional filtration efficiency, ensuring fine particle, contaminant and impurity removal from liquids and gases. Compacting and heating stainless steel particles creates a porous, uniform structure. This enables precise filtration and high particle retention with superior performance.

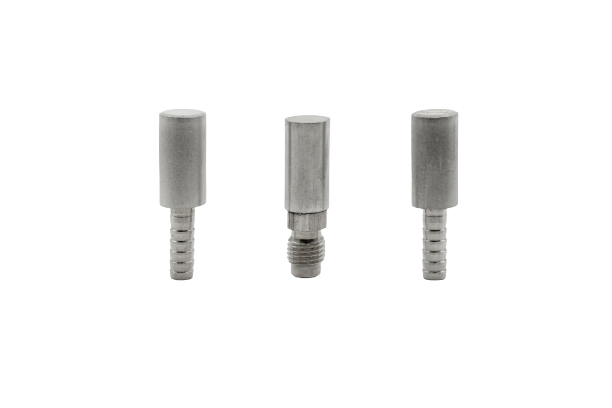

A key advantage is versatility in filtration ratings. Available in diverse pore sizes, sintered stainless steel filters allow customization for sector and application needs. Whether removing coarse debris or capturing submicron particles, the filters adapt to diverse requirements.

Industrial processes often involve high temperatures and aggressive chemicals, making temperature and chemical resistance critical for filtration systems. Sintered stainless steel filters excel in challenging environments. Stainless steel’s exceptional corrosion and temperature resistance suits these filters to various applications. They withstand extreme temperatures, resist chemical degradation and maintain performance over time.

Robust and durable, sintered stainless steel filters possess excellent mechanical strength and integrity, ensuring longevity and reliability. They endure high pressure differentials, repeated cleaning and stress without compromising efficiency. Durability reduces maintenance and replacements, saving costs.

Sintered stainless steel filters facilitate easy cleaning and maintenance, contributing to cost-effectiveness. Their rigid structure allows methods like backwashing, ultrasonic or chemical cleaning without damaging the media. Reusable unlike disposables, the filters minimize waste and costs.

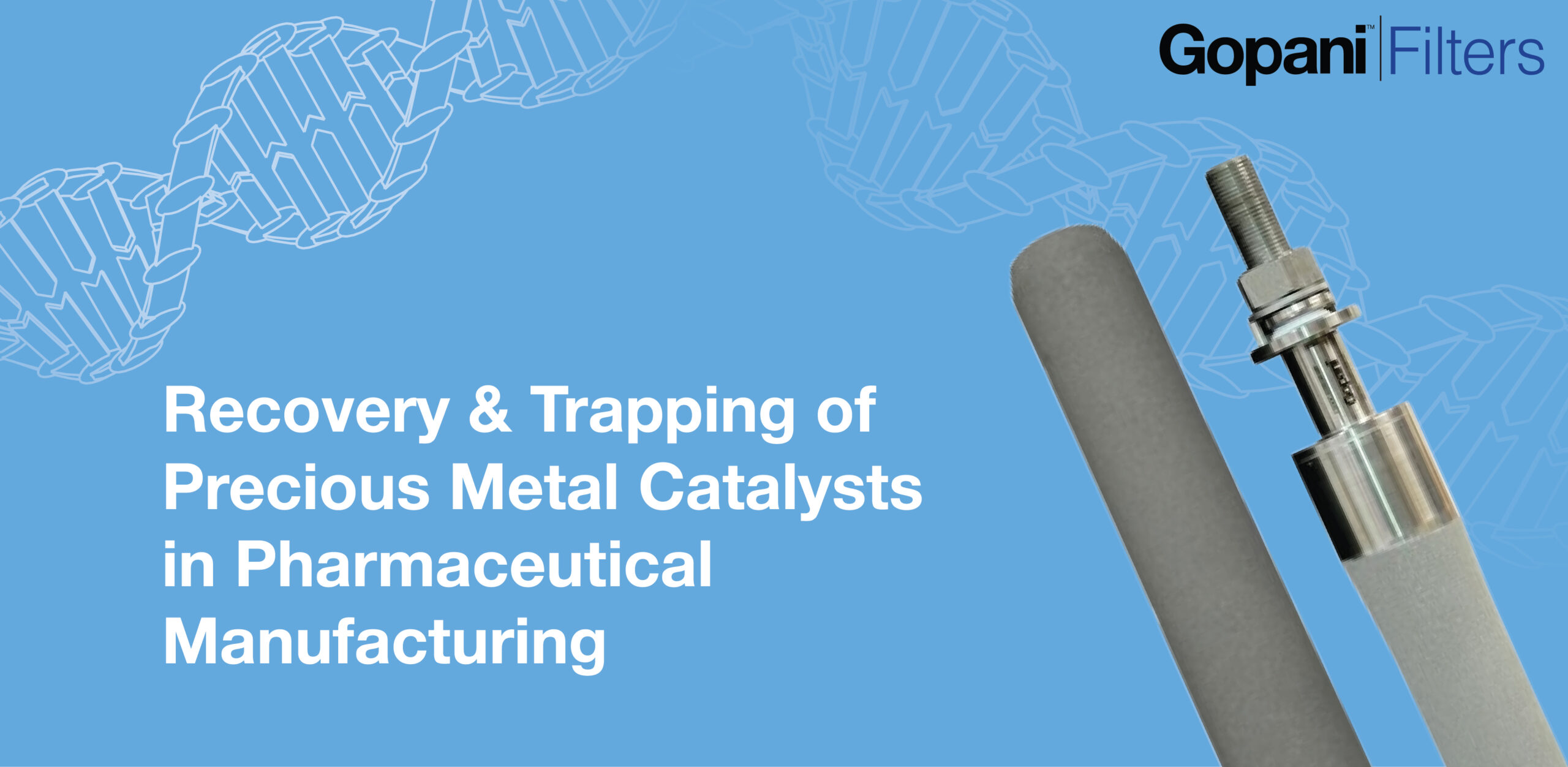

With applications across industries like oil, gas, chemical processing, pharmaceuticals, food, beverage, water treatment, and more, sintered stainless steel filters are used for critical processes such as gas/liquid separation, catalyst recovery, steam filtration, sterile air filtration, and product purification. Their versatility and adaptability suit them to diverse industrial needs.

In summary, Gopani’s sintered stainless steel filters appear poised to shape industrial filtration’s future. As sectors seek more reliable and effective solutions, these filters offer performance, longevity, and cost-effectiveness. Choosing them can enhance product quality, increase operational efficiency and reduce maintenance costs. Embracing this innovative technology will likely enable a new era in industrial filtration.

Standards

ISO 12500-3 in gas = Air and ASTM F795 in Liquid = Water

Types of Sintered Filter Elements

Factors to Consider before Buying a Sintered Cartridge Filter

- Operating conditions (temperature, pressure and flow rate)

- Filtration precision and filtration efficiency

- Appropriate material (corrosion resistance and high temperature resistance)

- Allowable pressure drop

- Appropriate medium strength (tensile strength, fatigue strength and load capacity)

Sintered Filter Elements and Systems for Tailored for Industries Like

Pharmaceuticals and API

Speciality Chemicals

Food and Beverage

Transportation

Refining and Petrochemicals

Fine Chemical

Instrumentation

Diagnostics

Have Questions About Our Product ?

Drop in your Requirement Details

Talk to our representative to get insight on which product will suit you.

Related Blogs