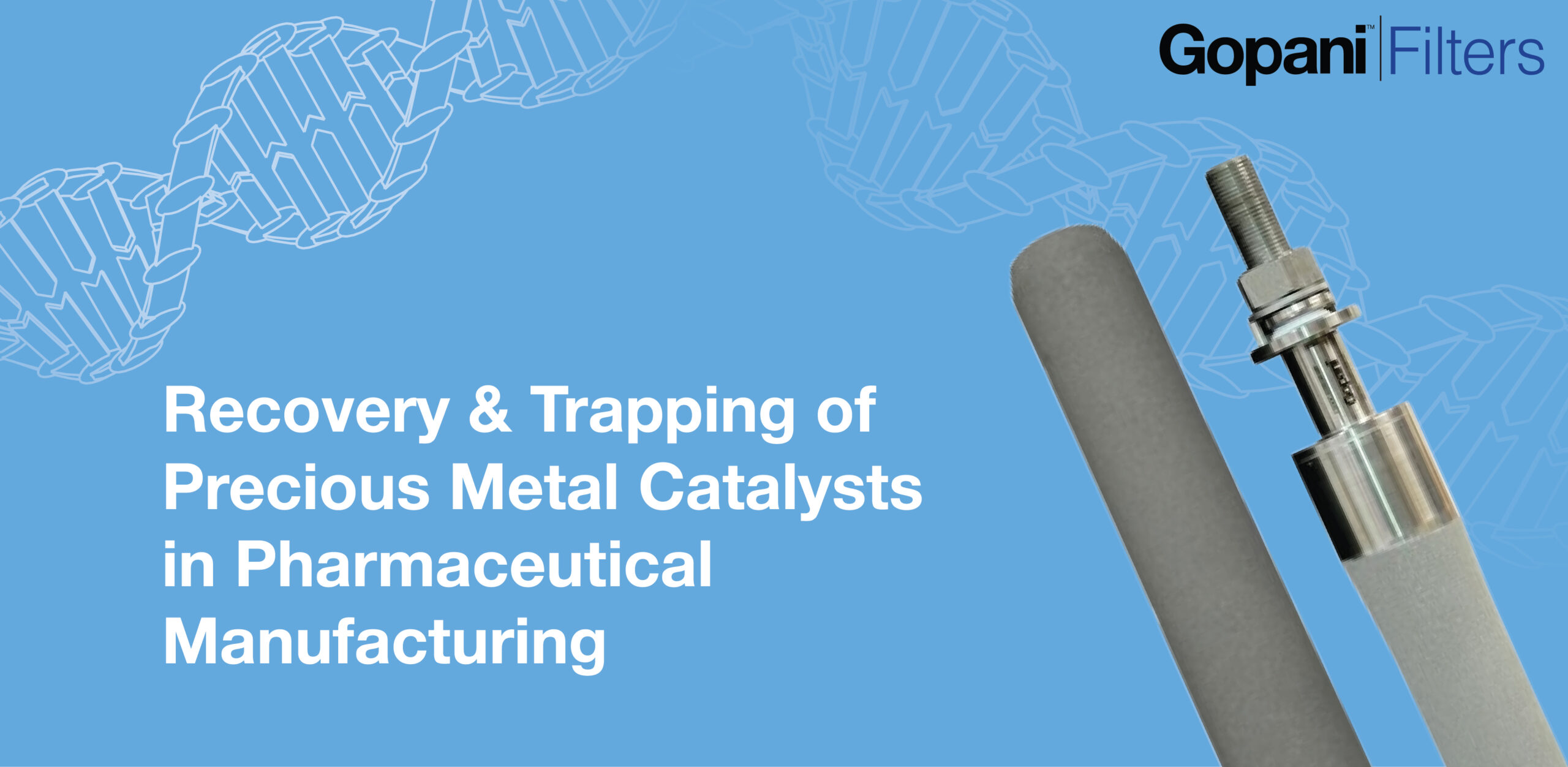

Catalyst recovery is a critical process for many industrial facilities that use catalysts to enable chemical reactions. Ensuring maximum catalyst lifespan and performance requires an effective catalyst filtration system to catch metals and particles before they are lost.

At Gopani, we offer innovative sintered metal filter elements custom-engineered for all your catalyst recovery needs. Our high-precision liquid-solid filtration systems are compatible with a wide range of temperatures, flows, and other operating parameters for various catalyst types.

Our custom sintered metal filters can:

- Recover valuable precious metals and rare earth particles.

- Protect downstream product by preventing catalyst leakage into further processes.

- Reduce maintenance costs through long-lasting filter elements and automated cleaning.

Retrofit filter candles in existing filtration systems from other manufacturers

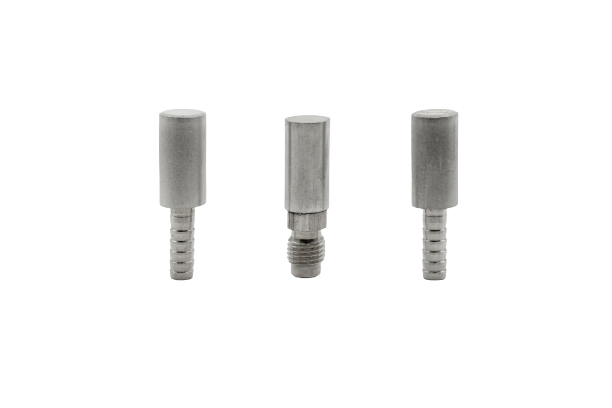

Our sintered metal powder filter elements are made from corrosion-resistant materials like stainless steel, titanium alloys, Hastelloy, and Inconel. They feature:

- High surface area for efficient particle capture.

- Long service lifetimes through robust construction.

- Higher filtration efficiency down to micron and sub-micron levels.

- Ability to withstand harsh conditions like high heat, corrosives, and physical wear.

We offer custom elements in tubes, plates, discs, and more with connections like welded ends, threads, and clamps.

Gopani’s integrated services include design, engineering, and commissioning of turnkey filtration systems for your specific needs – from lab-scale units to large-scale plants.

If your facility requires an effective catalyst recovery solution for precious metal recovery, environment protection, or cost reduction, contact us today.

Our team of experts can review your application, recommend the optimal sintered metal filter technology, and install a customized catalyst filtration system to meet your objectives.

Standards

ISO 12500-3 in gas = Air and ASTM F795 in Liquid = Water

Types of Sintered Filter Elements

Factors to Consider before Buying a Sintered Cartridge Filter

- Operating conditions (temperature, pressure and flow rate)

- Filtration precision and filtration efficiency

- Appropriate material (corrosion resistance and high temperature resistance)

- Allowable pressure drop

- Appropriate medium strength (tensile strength, fatigue strength and load capacity)

hydrogenation reaction, Green Chemistry, Catalyst recycling, raney nickel reaction, Hydrogenation Catalyst, Sustainable Manufacturing, Alkylation Catalysts, raney nickel catalyst particle size, Extending porous sintered filter lifespan, High nickel alloy porous filters, Low pressure catalyst filtration, Particle Agglomeration, Prototype porous sintered filters, Supported catalyst filtration, charcoal in pharma plants, catalytic hydrogenation of benzene gives, Transition Metal Complexes, Catalyst Attrition, hydrogenation of ethyne, Nickel Catalysts, Coal Combustion, hydrogen peroxide manganese dioxide, Precious Metal Catalyst Filters, raney nickel catalyst reaction, Hydrogenation Catalysts, Hydrodenitrogenation Catalysts, hydrogenation using raney nickel catalyst, raney nickel catalyst grade, Batch catalyst filtration, Catalyst Sintering, Ceramic catalyst filters, Customized sintered filter solutions, Disc Filter Manufacturers in India, Hastelloy catalyst filters, Hot catalyst filtration, Improved porous tube stability, Metal nanoparticle catalyst filtration, Metallic Filter Manufacturers in India, Multi Tube Filter Manufacturers in India, Nanocatalyst filtration, Palladium Catalyst Filters, Petrochemical Processing filters, vanadium pentoxide, raney catalyst, Reaction Kinetics, Hydrodesulfurization Catalysts, Catalyst Deactivation, Methanol synthesis Catalysts, raney nickel catalyst Filtration, raney nickel catalyst hazards, raney nickel catalyst manufacture, raney nickel catalyst safety

Sintered Filter Elements and Systems for Tailored for Industries Like

Pharmaceuticals and API

Speciality Chemicals

Food and Beverage

Transportation

Refining and Petrochemicals

Fine Chemical

Instrumentation

Diagnostics

explain hydrogenation of alkenes, raney nickel type catalyst, Catalyst Degradation, Catalyst filter replacement, Catalyst residue removal, Continuous catalyst filtration, Crossflow catalyst filtration, Custom porous sintered metal filters, Gas-Solid Reactions, Glass microfiber catalyst filters, Manual catalyst filtration, Noble Metal Catalyst Filter, Optimizing porous sintered tube performance, Seamless porous sintered metal filter, Silver Catalyst Filters, Sintered powder filter manufacturing, Ultrafine catalyst filters, hydrogenation of alkynes, Process Intensification, nickel catalyst for hydrogenation, hydrogenation of oil catalyst, Reactor Performance, Cracking Catalysts, Molybdenum Catalysts, precious metal catalysts recovery, Ammonia synthesis Catalysts, Nitrogen oxide reduction Catalysts, Catalyst Elutriation, Drum Filter Manufacturers in India, High temperature catalyst filtration, Large pore catalyst filters, Removal of activated carbon, Solvent resistant catalyst filters, Welded catalyst filter cartridges, catalytic hydrogenation of vegetable oil is also known as, Erosion, catalyst used in hydrogenation of oil, Catalyst Support, Zeolites Catalysts, catalyst hopper fluidization, Raney Nickel Catalyst Filtration, Catalyst Circulation, Catalyst Filters for Precious Metal Catalysts, Enhanced sintered filter durability, Gold Catalyst Filters, High-precision Pore size, Spent catalyst filtration, hydrogenation meaning, Heat Transfer, Reactor Design, catalyst filter, Mass Transfer, Homogeneous Catalysis, Environmental Catalysis, Palladium Catalysts, Alkali resistant catalyst filters, Catalyst Circulation filtration, Catalyst Filtration Safety Standards, Catalytic Activity Filters, Cricket Filter Manufacturers in India, Disposable catalyst filter bags, Membrane catalyst filtration, Safety Filter Manufacturers in India, Sintered filter retrofits, Sintered metal catalyst filters

Have Questions About Our Product ?

Drop in your Requirement Details

Talk to our representative to get insight on which product will suit you.

Related Blogs