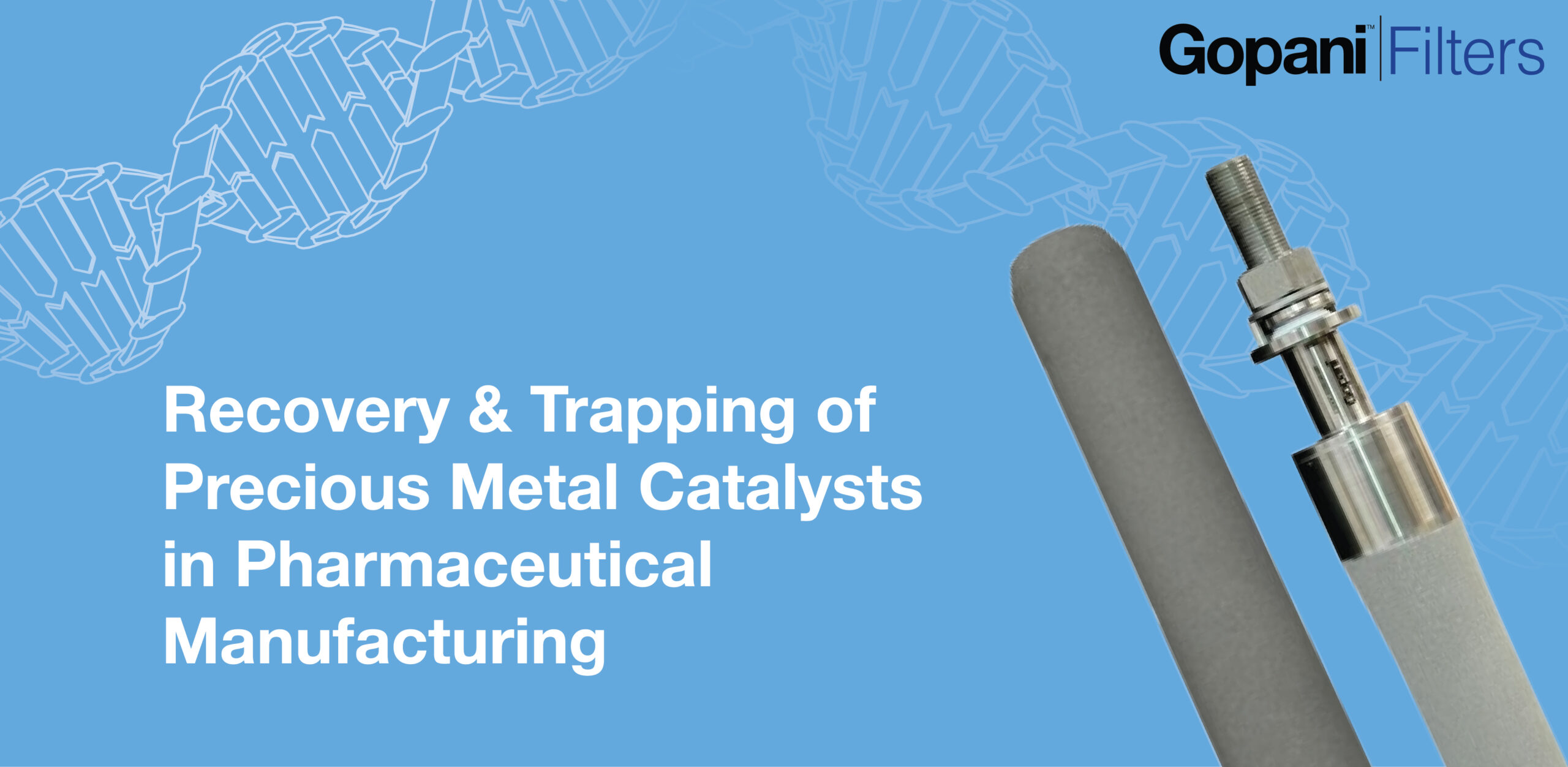

Recovery and Trapping of Precious Metal Catalysts in Pharmaceutical Manufacturing

Written by dharmagnagopanigmail-com

The process of making pharmaceutical products/drugs often involves precious metal catalysts such as Platinum (Pt), Palladium (Pd), and Rhodium (Rh), which are important for various chemical reactions. These catalysts are used to speed up reactions, lower energy requirements, and ensure that specific transformations occur effectively.

Once the process is complete, it is important to remove these metal catalysts. If left in the product, they can significantly alter the properties of the final pharmaceutical compound, potentially leading to contamination. Additionally, recovering these metals helps reduce operational costs, as they can be reused in future processes.

The Role of Catalysts in Modern Pharmaceutical Production

Precious metal catalysts like PdC, PtC, and Raney Nickel play a crucial role in these pharmaceutical processes, ensuring high-quality reactions while minimizing production costs. Efficient filtration not only prevents contamination but also aids in the recovery of these costly materials, reducing overall operational expenses.

Pharmaceutical catalysis is a key component in the production of modern drugs. It involves using catalysts to speed up chemical reactions, making the creation of active pharmaceutical ingredients (APIs) more efficient and precise. Important catalysts in this field include Palladium on Carbon (PdC), Platinum on Carbon (PtC), and Raney Nickel. These catalysts play crucial roles in transforming raw materials into essential medications.

PdC and PtC are particularly effective in hydrogenation reactions, where they add hydrogen atoms to molecules, converting double bonds into single bonds and stabilizing the molecules. Raney Nickel, known for its high surface area, is also highly efficient in hydrogenation, making it valuable in pharmaceutical production.

Precious Metal Catalysts, while expensive, are highly efficient and selective, ensuring smooth reactions with fewer by-products. This efficiency justifies their cost, but it also makes their recovery and recycling essential to reduce expenses in pharmaceutical manufacturing. Overall, these catalysts are indispensable in drug synthesis, enhancing production efficiency and highlighting the importance of innovation in pharmaceutical chemistry. By leveraging these catalysts, we can continue to develop better, more effective medications that improve lives worldwide.

The Importance of Filtration in Catalyst Recovery

Efficient filtration is important to address challenges such as clogging, fouling, and varying catalyst particle sizes. These issues can significantly impact the recovery and reuse of precious metal catalysts, making filtration methods crucial for maintaining product quality and process efficiency.

Depth Filtration is a method used to capture fine particles and ensure maximum catalyst recovery. This technique involves using filters with multiple layers of filtration media, which trap contaminants throughout the entire filter matrix.

Cartridge Filters is another solution for pharmaceutical filtration. These filters come in various designs, to capture catalyst particles.

Crossflow Filtration Systems represent advanced technology used to maintain catalyst integrity while filtering. Unlike traditional filtration methods, crossflow systems allow the feed solution to flow tangentially across the filter surface.

Common issues in filtration processes include the loss of catalyst, contamination, and product loss. Addressing these challenges is essential to maintain product purity and prevent contamination, which is critical in drug production. Effective filtration not only ensures the quality of the final product but also enhances the overall efficiency of the manufacturing process.

Gopani’s Filtration Solutions for Pharma Applications offer solutions for precious metal catalyst recovery. Our customizable filters are designed to ensure cost-efficiency, making them an ideal choice for pharmaceutical manufacturers. Gopani’s solutions include a range of filtration products that can be tailored to meet the specific needs of different processes, ensuring optimal performance and minimal product loss.

Efficient filtration is key to catalyst recovery, cost savings, and maintaining product purity in pharmaceutical applications.

Trust Gopani to provide the best filtration solutions for your needs.

The role of filtration in pharmaceutical applications involving precious metal catalysts cannot be overstated. Efficient filtration methods not only enhance catalyst recovery and cost savings but also ensure the purity and quality of the final product. By leveraging advanced filtration technologies, pharmaceutical manufacturers can achieve greater efficiency in their production processes. For reliable and effective filtration solutions, Gopani stands out as a trusted partner in the pharma industry.

Filtration Efficiency

The efficiency values below are given for air and water at a given flow rate.

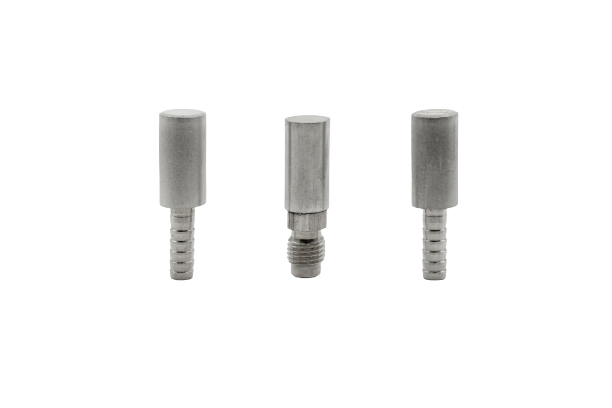

Types of Sintered Filter Elements

Factors to Consider before Buying a Sintered Cartridge Filter

- Operating conditions (temperature, pressure and flow rate)

- Filtration precision and filtration efficiency

- Appropriate material (corrosion resistance and high temperature resistance)

- Allowable pressure drop

- Appropriate medium strength (tensile strength, fatigue strength and load capacity)

Sintered Filter Elements and Systems for Tailored for Industries Like

Pharmaceuticals and API

Speciality Chemicals

Food and Beverage

Transportation

Refining and Petrochemicals

Fine Chemical

Instrumentation

Diagnostics

Have Questions About Our Product ?

Drop in your Requirement Details

Talk to our representative to get insight on which product will suit you.

Related Blogs