ACHEMA 2024: Unleash the Power of Precision Filtration with Gopani Filters – Hall 5.0, Stand E61

Written by dharmagnagopanigmail-com

Gopani Filters Private, Limited. invites you to experience the future of filtration at ACHEMA 2024 in Frankfurt, Germany! Join us at Hall 5.0, Stand E61 to explore our comprehensive range of industry leading filtration solutions.

Filtration plays a critical role in countless industrial processes, ensuring optimal performance and protecting valuable equipment. Selecting the right filter media is essential for achieving desired results. At Gopani Filters, We understand this intricate relationship and translate it into innovative solutions.

Unveiling a World of Filtration Excellence:

Top-Selling Filter Range: Discover our best selling Polymer media and inorganic media filter cartridges. We will showcase our high-performance pleated, string wound, meltblown filters, and award winning filtration solutions.

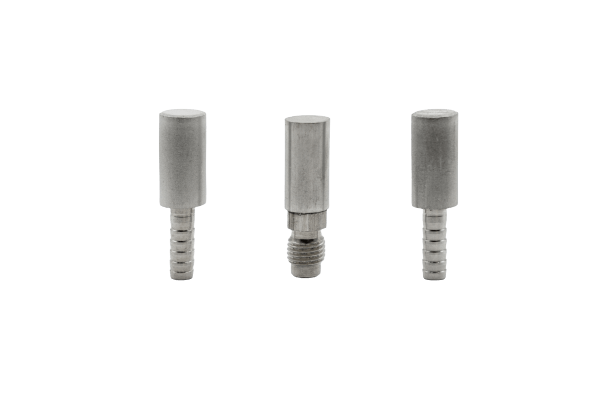

Sintered Porous Metal Filter Elements: Explore our advanced line of porous metal sintered filters, including porous metal sintered tubes & cartridges, porous metal sintered filter candles for catalyst recovery, spargers and carbonation stones for gases, diffusion discs, and elements for gas and flashback arrestors.

Gopani Filters: Your Partner in Precision Filtration:

At Gopani Filters, we are committed to providing customized solutions that meet your specific filtration needs. Our expert team will be on hand at ACHEMA to discuss your requirements and recommend the perfect filtration product for your application.

Don’t miss this opportunity to:

- Witness the latest advancements in filtration technology.

- Discuss your filtration challenges with our filtration specialists.

- Discover how Gopani Filters can optimize your process efficiency and product quality.

Visit us at Hall 5.0, Stand E61, and let’s unlock the power of precision filtration together!

Filtration Efficiency

The efficiency values below are given for air and water at a given flow rate.

Standards

ISO 12500-3 in gas = Air and ASTM F795 in Liquid = Water

Types of Sintered Filter Elements

Factors to Consider before Buying a Sintered Cartridge Filter

- Operating conditions (temperature, pressure and flow rate)

- Filtration precision and filtration efficiency

- Appropriate material (corrosion resistance and high temperature resistance)

- Allowable pressure drop

- Appropriate medium strength (tensile strength, fatigue strength and load capacity)

Sintered Filter Elements and Systems for Tailored for Industries Like

Pharmaceuticals and API

Speciality Chemicals

Food and Beverage

Transportation

Refining and Petrochemicals

Fine Chemical

Instrumentation

Diagnostics

Have Questions About Our Product ?

Drop in your Requirement Details

Talk to our representative to get insight on which product will suit you.

Related Blogs