Comprehensive Selection Guide for Crafting Your Personalized Diffusion Stone

Written by dharmagnagopanigmail-com

When it comes to customizing your personal diffusion stone, understanding the factors that influence its operation is crucial. Here’s an in-depth five-step selection guide to aid you in this bespoke creation process:

Identify the Gas and Liquid Pairing:

Your journey begins with identifying the specific gas and liquid you’ll be using. Each pair possesses unique properties that can impact the diffusion process. For instance, a gas with high solubility in your chosen liquid may necessitate a larger or more porous stone to achieve optimal diffusion.

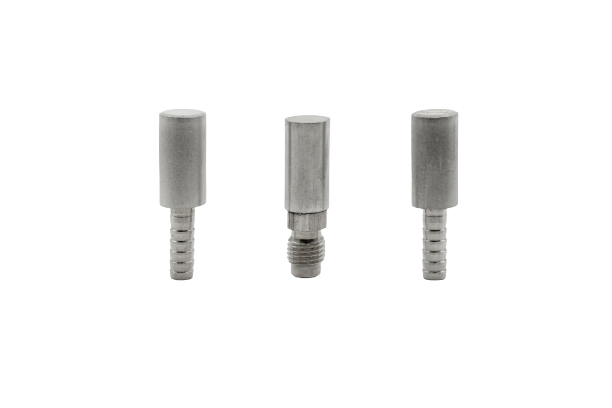

Size, Shape, and Material Selection:

The dimensions, form, and material of your diffusion stone significantly affect its performance. A larger stone with an extensive surface area might offer enhanced diffusion, yet it may also present challenges in terms of cleanliness and maintenance. Additionally, the selected material plays a pivotal role. While stainless steel offers durability and resistance to corrosion, it could be pricier than alternatives like plastic, which, while more affordable, might not offer the same level of durability or heat resistance.

Decide on Pore Size:

The size of the pores in your diffusion stone directly influences the size of the bubbles released, which in turn impacts the diffusion rate. Smaller pores might generate finer bubbles that are ideal for efficient diffusion, but they could also be more prone to blockages.

Determine the Flow Rate:

The flow rate of both the liquid and gas through your diffusion stone plays an integral role in the diffusion rate. A higher flow rate could lead to more efficient diffusion, but it might also heighten the risk of clogs or potential damage to your stone.

Considerations for Cost and Maintenance:

While crafting your unique diffusion stone can be cost-effective, it’s essential to consider the ongoing maintenance and replacement costs. Ensure you incorporate the cost of materials, labor, and any additional equipment or supplies necessary for the production and upkeep of your stone.

Armed with this comprehensive selection guide, you’ll be well-prepared to create a diffusion stone that’s tailored to your specific needs, optimizing your diffusion process.

Stainless Steel Micron Diffusion Stone, stainless steel diffusion stone, 2 micron diffusion stone, carbonation, Small bubbles transfer gases faster, carbonation stone, beer for carbonation stone, food beverages for carbonation stone, Carb Stone, Carbonation Stone, China Diffusion Stone, hengko, diffuser stone, diffusion stone, ozone stone, Sparger

Sintered Filter Elements and Systems for Tailored for Industries Like

Pharmaceuticals and API

Speciality Chemicals

Food and Beverage

Transportation

Refining and Petrochemicals

Fine Chemical

Instrumentation

Diagnostics

Standards

ISO 12500-3 in gas = Air and ASTM F795 in Liquid = Water

Types of Sintered Filter Elements

Factors to Consider before Buying a Sintered Cartridge Filter

- Operating conditions (temperature, pressure and flow rate)

- Filtration precision and filtration efficiency

- Appropriate material (corrosion resistance and high temperature resistance)

- Allowable pressure drop

- Appropriate medium strength (tensile strength, fatigue strength and load capacity)

Petrochemical Processing, Pharmaceutical Manufacturing filters, Porous sintered filter cleaning, Precious Metal Recovery Filters, Reconditioning porous sintered filters, Recovery or Filtration of noble metal catalysts, Removal of activated carbon, Reusable catalyst filter bags, Sintered metal filter manufacturing pioneers, Small batch sintered filter production, Solvent resistant catalyst filters, Welded catalyst filter cartridges, Zero Hold-up filters, catalytic hydrogenation of vegetable oil is also known as, raney nickel, Computational Fluid Dynamics, vanadium pentoxide, raney catalyst, Fluidized Bed Reactor, Waste Incineration, Ruthenium, Heterogeneous Catalysis, catalytic hydrogenation of alkenes, Reaction Kinetics, catalyst recovery filters, Hydrodesulfurization Catalysts, Multiphase Flow, hydrogenation of benzene, Bubble Dynamics, raney nickel catalyst supplier, Catalyst Deactivation, Catalyst recovery, Methanol synthesis Catalysts, explain hydrogenation of alkenes, raney nickel catalyst Filtration, Carbon catalyst filtration, raney nickel catalyst applications, raney nickel catalyst filter system, raney nickel catalyst hazards, raney nickel catalyst manufacture, raney nickel catalyst safety, raney nickel type catalyst, solid Catalyst Filter Raney Nickel, stabilized raney nickel catalyst, Bleaching earth removal in Vegetable oil plants, Catalyst Degradation, Catalyst Filter For Raney Nickel Filtration

Have Questions About Our Product ?

Drop in your Requirement Details

Talk to our representative to get insight on which product will suit you.

hydrogenation meaning, catalyst recovery, catalyst hopper, Heat Transfer, Reactor Design, catalyst filter, Transition Metal Complexes, Mass Transfer, Catalyst Attrition, hydrogenation of ethyne, Homogeneous Catalysis, Nickel Catalysts, Coal Combustion, hydrogen peroxide manganese dioxide, Environmental Catalysis, Precious Metal Catalyst Filters, raney nickel catalyst reaction, adium Catalysts, Hydrogenation Catalysts, Hydrodenitrogenation Catalysts, Reforming Catalysts, Catalyst Recovery Filtration, hydrogenation using raney nickel catalyst, raney nickel catalyst activation, raney nickel catalyst grade, raney nickel catalyst manufacturer, spent raney nickel catalyst, Acid resistant catalyst filters, Alkali resistant catalyst filters, Batch catalyst filtration, Catalyst Activity Loss, Catalyst Circulation filtration, Catalyst Filtration Safety Standards, Catalyst Sintering, Catalyst filter cleaning, Catalyst polishing filters, Catalyst separation, Catalyst slurry filtration, Catalytic Activity Filters, Ceramic catalyst filters, Cricket Filter Manufacturers in India, Customized sintered filter solutions, Disc Filter Manufacturers in India, Disposable catalyst filter bags, Hastelloy catalyst filters, Hot catalyst filtration, Improved porous tube stability, Membrane catalyst filtration, Metal nanoparticle catalyst filtration, Metallic Filter Manufacturers in India, Multi Tube Filter Manufacturers in India

Related Blogs