Catalyst

Recovery

Excellent Filtration Efficiency for Higher Recovery of Catalyst

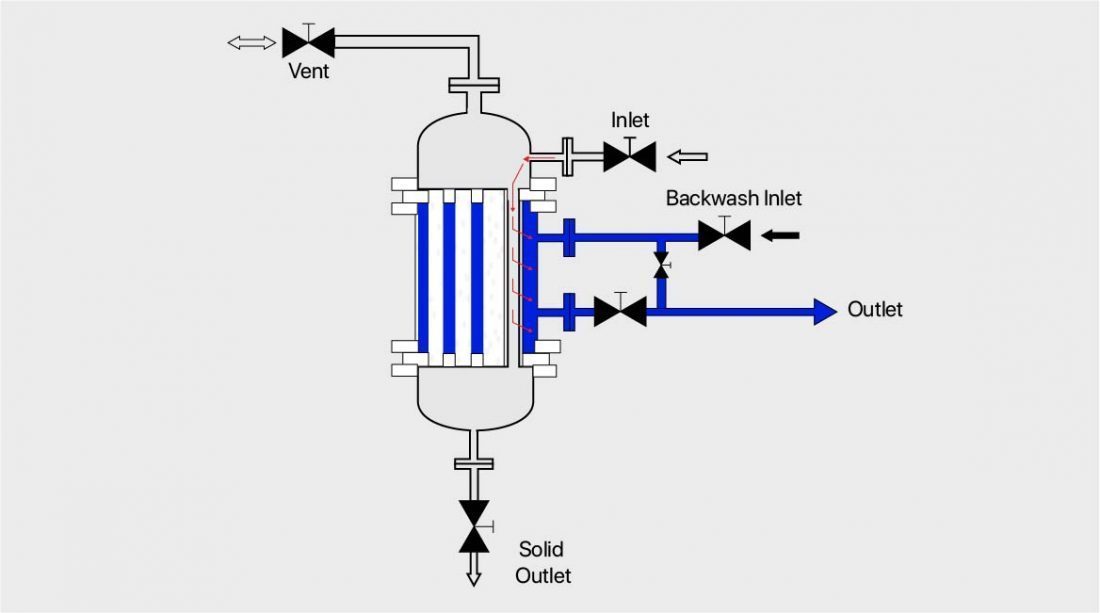

Sintered powder metal filter systems from Gopani filters solve problem of catalyst leakage and loss of precious metal in the pharmaceutical and specialty chemicals industry.

The porous metal catalyst trapping filters have high resistance to excessively harsh chemicals, reactive solvents and corrosive liquids. They can also withstand high temperatures from cryogenic – 150° C to 900° C. The filter elements can easily withstand vibrations, resist abrasions and have high differential pressure capabilities. All these capabilities make the sintered powder metal filter systems for recovery of precious metals and catalyst filtration, extremely long lasting with excellent filtration consistency and capability.

The Indian Chemical Industry is clearly emerging as a manufacturing hub to service the global markets. In this process, the challenges and opportunities in the area of Sintered Metal Powder Filtration are surfacing too. Gopani Filters is proud to be the a key player in this high-tech field offering world class products based on indigenous technology. We are a leading manufacturer of filter elements and filtration systems and offer a broad range of innovative filtration solutions for diverse industrial applications.

We are one of the few manufacturers in the world producing sintered metal powder filters for efficient and flawless Catalyst Filtration and Catalyst Trapping applications that can withstand harsh and highly demanding operating conditions. Our comprehensive range of filter elements and filtration systems are made from top quality Stainless Steel, Nickel, Monel, and many other metals.

We at Gopani Filters are focussed on partnering with our customers to create and deliver higher value through our turnkey filter skids and precious metal catalyst filters. Our Design & Service Team at Ahmedabad works closely with our customers to achieve optimal filtration performance in Catalyst Filtration & Catalyst Trapping applications. Here are some of the key challenges on which we will be happy to work with you:

Retrofits: How to get more” out of the current filtration system with lowest possible investment is always a priority matter for manufacturing professionals. We can work with you to retrofit your existing filtration system to improve its performance and extend its lifespan significantly.

Redesigning: We understand that in order to become more efficient and competitive, you may have to redesign filtration systems to meet the unique requirements. Our team will be happy to work with your team to achieve this objective.

Trouble shooting: The changes made in production process or catalyst system may throw certain unforeseen issues hampering production. We will be happy to help you in removing these bottlenecks.

Timely, Quicker Delivery: We consider “Fastest Possible Delivery” as our living philosophy. We live by our promises on delivery schedule committed to our customers minimizing downtime, ensuring uninterrupted production, and avoiding project delays.

Sales & Service Team that listens to Customers: Through our people and our distribution network, we stay in close touch with our customers to exchange and act on ideas related to saving costs, improving efficiency, designing tailor-made systems, and delivering satisfactory after-sales service. By partnering with us, you will be able to build a reliable and trusted supply chain in the area of filtration for your company.

Therefore, for all your filtration needs, please get in touch with us. Our Sales & Service team will be happy to present more information of our innovative filtration solutions and collaborate with you to achieve excellence in filtration.

hydrogenation reaction, Green Chemistry, Catalyst recycling, raney nickel reaction, Hydrogenation Catalyst, Sustainable Manufacturing, Alkylation Catalysts, raney nickel catalyst particle size, Extending porous sintered filter lifespan, High nickel alloy porous filters, Low pressure catalyst filtration, Particle Agglomeration, Prototype porous sintered filters, Supported catalyst filtration, charcoal in pharma plants, catalytic hydrogenation of benzene gives, Transition Metal Complexes, Catalyst Attrition, hydrogenation of ethyne, Nickel Catalysts, Coal Combustion, hydrogen peroxide manganese dioxide, Precious Metal Catalyst Filters, raney nickel catalyst reaction, Hydrogenation Catalysts, Hydrodenitrogenation Catalysts, hydrogenation using raney nickel catalyst, raney nickel catalyst grade, Batch catalyst filtration, Catalyst Sintering, Ceramic catalyst filters, Customized sintered filter solutions, Disc Filter Manufacturers in India, Hastelloy catalyst filters, Hot catalyst filtration, Improved porous tube stability, Metal nanoparticle catalyst filtration, Metallic Filter Manufacturers in India, Multi Tube Filter Manufacturers in India, Nanocatalyst filtration, Palladium Catalyst Filters, Petrochemical Processing filters, vanadium pentoxide, raney catalyst, Reaction Kinetics, Hydrodesulfurization Catalysts, Catalyst Deactivation, Methanol synthesis Catalysts, raney nickel catalyst Filtration, raney nickel catalyst hazards, raney nickel catalyst manufacture, raney nickel catalyst safety, solid Catalyst Filter Raney Nickel, Bleaching earth removal in Vegetable oil plants, Catalyst Particle Agglomeration, Catalyst Regeneration filters, Exotic alloy sintered filters, Fine catalyst filters, Heterogeneous catalyst filtration, High performance sintered filter components, High pressure catalyst filtration, Rotary vacuum catalyst filters, Sintered filter retrofitting, World-class Indian porous sintered filters, sintered Filter tube pilot production, the catalyst used in the hydrogenation of ethene to ethane, Platinum, hydrogenation, hydrogenation of alkenes, Biomass Gasification, catalyst filtration, Hydrodynamic Behavior, co2 hydrogenation to methanol, Catalyst Regeneration, raney nickel formula, catalyst filtration system, Rhodium Catalysts, Catalyst Filters, Fixed Bed Reactor, Catalyst Lifecycle Management, Catalyst Lifespan, Catalyst cake filtration, Nano-Mag Technologies Pvt. Ltd., Pharmaceutical Manufacturing filters, Porous sintered filter cleaning, Reconditioning porous sintered filters, Recovery or Filtration of noble metal catalysts, Reusable catalyst filter bags, Small batch sintered filter production, Zero Hold-up filters, Rhodium, hydrogenation process, catalyst filters, catalytic hydrogenation, GKN Sinter Metals, Oxidation Catalyst, raney nickel activation, Catalyst Recovery Filtration System Manufacturer, raney nickel catalyst ph, raney nickel catalyst sigma, Ambient catalyst filtration, Catalyst Fluidization, Catalyst filter sealing, Catalytic Selectivity Filters, Custom engineered porous sintered filters, Damaged porous filter restoration, Dome Filter Manufacturers in India, Filtration of hazardous liquids, Fine Chemical Synthesis filters, Indian sintered filter innovation, Inline Filter Manufacturing Companies in India, Platinum Catalyst Filters, Polishing Filter Manufacturers in India, Refurbishing sintered filters, Replacement sintered filters, Rhodium Catalyst Filters, Sintered filter regeneration, Sparkler Filter Manufacturers in India, Specialty porous metal filters, Hydrogenation Catalysts Filter, heterogeneous chemical reaction engineering, catalyst recovery, catalyst hopper, Reforming Catalysts

Popular for Applications Like

- Specialty Chemicals

- API and Pharmaceuticals

hydrogenation reaction, Green Chemistry, Catalyst recycling, raney nickel reaction, Hydrogenation Catalyst, Sustainable Manufacturing, Alkylation Catalysts, raney nickel catalyst particle size, Extending porous sintered filter lifespan, High nickel alloy porous filters, Low pressure catalyst filtration, Particle Agglomeration, Prototype porous sintered filters, Supported catalyst filtration, charcoal in pharma plants, catalytic hydrogenation of benzene gives, Transition Metal Complexes, Catalyst Attrition, hydrogenation of ethyne, Nickel Catalysts, Coal Combustion, hydrogen peroxide manganese dioxide, Precious Metal Catalyst Filters, raney nickel catalyst reaction, Hydrogenation Catalysts, Hydrodenitrogenation Catalysts, hydrogenation using raney nickel catalyst, raney nickel catalyst grade, Batch catalyst filtration, Catalyst Sintering, Ceramic catalyst filters, Customized sintered filter solutions, Disc Filter Manufacturers in India, Hastelloy catalyst filters, Hot catalyst filtration, Improved porous tube stability, Metal nanoparticle catalyst filtration, Metallic Filter Manufacturers in India, Multi Tube Filter Manufacturers in India, Nanocatalyst filtration, Palladium Catalyst Filters, Petrochemical Processing filters, vanadium pentoxide, raney catalyst, Reaction Kinetics, Hydrodesulfurization Catalysts, Catalyst Deactivation, Methanol synthesis Catalysts, raney nickel catalyst Filtration, raney nickel catalyst hazards, raney nickel catalyst manufacture, raney nickel catalyst safety, solid Catalyst Filter Raney Nickel, Bleaching earth removal in Vegetable oil plants, Catalyst Particle Agglomeration, Catalyst Regeneration filters, Exotic alloy sintered filters, Fine catalyst filters, Heterogeneous catalyst filtration, High performance sintered filter components, High pressure catalyst filtration, Rotary vacuum catalyst filters, Sintered filter retrofitting, World-class Indian porous sintered filters, sintered Filter tube pilot production, the catalyst used in the hydrogenation of ethene to ethane, Platinum, hydrogenation, hydrogenation of alkenes, Biomass Gasification, catalyst filtration, Hydrodynamic Behavior, co2 hydrogenation to methanol, Catalyst Regeneration, raney nickel formula, catalyst filtration system, Rhodium Catalysts, Catalyst Filters, Fixed Bed Reactor, Catalyst Lifecycle Management, Catalyst Lifespan, Catalyst cake filtration, Nano-Mag Technologies Pvt. Ltd., Pharmaceutical Manufacturing filters, Porous sintered filter cleaning, Reconditioning porous sintered filters, Recovery or Filtration of noble metal catalysts, Reusable catalyst filter bags, Small batch sintered filter production, Zero Hold-up filters, Rhodium, hydrogenation process, catalyst filters, catalytic hydrogenation, GKN Sinter Metals, Oxidation Catalyst, raney nickel activation, Catalyst Recovery Filtration System Manufacturer, raney nickel catalyst ph, raney nickel catalyst sigma, Ambient catalyst filtration, Catalyst Fluidization, Catalyst filter sealing, Catalytic Selectivity Filters, Custom engineered porous sintered filters, Damaged porous filter restoration, Dome Filter Manufacturers in India, Filtration of hazardous liquids, Fine Chemical Synthesis filters, Indian sintered filter innovation, Inline Filter Manufacturing Companies in India, Platinum Catalyst Filters, Polishing Filter Manufacturers in India, Refurbishing sintered filters, Replacement sintered filters, Rhodium Catalyst Filters, Sintered filter regeneration, Sparkler Filter Manufacturers in India, Specialty porous metal filters, Hydrogenation Catalysts Filter, heterogeneous chemical reaction engineering, catalyst recovery, catalyst hopper, Reforming Catalysts

Have Questions About Our Product ?

Drop in your Requirement Details

Talk to our representative to get insight on which product will suit you.

Catalyst Recovery Filtration, raney nickel catalyst activation, raney nickel catalyst manufacturer, spent raney nickel catalyst, Acid resistant catalyst filters, Catalyst Activity Loss, Catalyst filter cleaning, Catalyst polishing filters, Catalyst separation, Catalyst slurry filtration, Nanostructured Catalysts, Plate and frame catalyst filters, Pleated catalyst filter cartridges, Polymer catalyst filters, Porous sintered filter repair, Pressure Leaf Filter Manufacturers in India, Refinery Operations filters, Stainless steel catalyst filters, raney nickel, Fluidized Bed Reactor, Ruthenium, catalytic hydrogenation of alkenes, catalyst recovery filters, hydrogenation of benzene, Carbon catalyst filtration, raney nickel catalyst applications, raney nickel catalyst filter system, stabilized raney nickel catalyst, Catalyst Filter For Raney Nickel Filtration, Catalyst Poisoning, Catalyst Regeneration Filters, Catalyst filter media, Catalyst filtration efficiency, Dead-end catalyst filtration, India sintered metal filter experts, Largest porous sintered filter producer in India, Organometallic catalyst filtration, Precision sintered metal filters, Reactor Operation, Sintered metal candle filters, Surface Filtration technology, Transition metal catalyst filtration, precious metal catalysts, palladium catalyst, raney nickel catalyst, catalyst recovery filter, Process Scale-up, vanadium pentoxide catalyst, Homogeneous catalyst filtration, raney nickel organic chemistry, Platinum Catalysts, Dehydrogenation Catalysts, Fischer-Tropsch synthesis Catalysts, Oxidation Catalysts, catalyst trapping, Coal Combustion Filters, raney nickel catalyst sds, raney nickel catalyst specification, Automated catalyst filtration, Catalyst Coking, Catalyst Cost Efficiency with filtration, Catalyst Fluidized Bed Technology, Filtration of Palladium, Improving sintered filter efficiency, Petrochemical Processing, Precious Metal Recovery Filters, Sintered metal filter manufacturing pioneers, Computational Fluid Dynamics, Waste Incineration, Heterogeneous Catalysis, Multiphase Flow, Bubble Dynamics, raney nickel catalyst supplier, Catalyst recovery, explain hydrogenation of alkenes, raney nickel type catalyst, Catalyst Degradation, Catalyst filter replacement, Catalyst residue removal, Continuous catalyst filtration, Crossflow catalyst filtration, Custom porous sintered metal filters, Gas-Solid Reactions, Glass microfiber catalyst filters, Manual catalyst filtration, Noble Metal Catalyst Filter, Optimizing porous sintered tube performance, Seamless porous sintered metal filter, Silver Catalyst Filters, Sintered powder filter manufacturing, Ultrafine catalyst filters, hydrogenation of alkynes, Process Intensification, nickel catalyst for hydrogenation, hydrogenation of oil catalyst, Reactor Performance, Cracking Catalysts, Molybdenum Catalysts, precious metal catalysts recovery, Ammonia synthesis Catalysts, Nitrogen oxide reduction Catalysts, Catalyst Elutriation, Drum Filter Manufacturers in India, High temperature catalyst filtration, Large pore catalyst filters, Removal of activated carbon, Solvent resistant catalyst filters, Welded catalyst filter cartridges, catalytic hydrogenation of vegetable oil is also known as, Erosion, catalyst used in hydrogenation of oil, Catalyst Support, Zeolites Catalysts, catalyst hopper fluidization, Raney Nickel Catalyst Filtration, Catalyst Circulation, Catalyst Filters for Precious Metal Catalysts, Enhanced sintered filter durability, Gold Catalyst Filters, High-precision Pore size, Spent catalyst filtration, hydrogenation meaning, Heat Transfer, Reactor Design, catalyst filter, Mass Transfer, Homogeneous Catalysis, Environmental Catalysis, Palladium Catalysts, Alkali resistant catalyst filters, Catalyst Circulation filtration, Catalyst Filtration Safety Standards, Catalytic Activity Filters, Cricket Filter Manufacturers in India, Disposable catalyst filter bags, Membrane catalyst filtration, Safety Filter Manufacturers in India, Sintered filter retrofits, Sintered metal catalyst filters

Gopani Solution Finder

Get Customized Solutions

Get customized solutions designed by filtration experts to solve critical filtration challenges.

Find Compatible Product

Surf through the widest range of sintered powder metal filters to find a compatible filter system and element.

Discuss Requirement

To know more about our product range or to discuss your requirements with our experts.