Minimizing Catalyst Attrition: A Comprehensive Guide

Written by dharmagnagopanigmail-com

Catalysts play a pivotal role in Chemical Engineering, speeding up reaction rates and making industrial processes more efficient. However, a major challenge in the field is catalyst attrition – the gradual wear and tear of catalysts leading to their degradation. In this blog, we explore strategies to minimize or completely stop catalyst attrition, with a focus on filtration solutions.

Understanding Catalyst Attrition

Catalyst attrition results from various factors such as Erosion, Catalyst Fluidization, Catalyst Sintering, and Catalyst Activity Loss. It’s particularly prevalent in processes like hydrogenation where metal catalysts such as Rhodium, Nickel Catalysts or Raney Nickel are used. This attrition often leads to Catalyst Activity Loss, impacting the efficiency of the hydrogenation process.

The Role of Filtration

Filtration, especially through high-quality filters like those produced by Gopani, can play a significant role in minimizing catalyst attrition. The importance of catalyst filtration and recovery is well-documented in Chemical Reaction Engineering and Environmental Catalysis. Catalyst filters, including Acid resistant catalyst filters, Alkali resistant catalyst filters, Ceramic catalyst filters, and Metallic Filter, can effectively trap catalyst particles, reducing their loss and extending their lifespan.

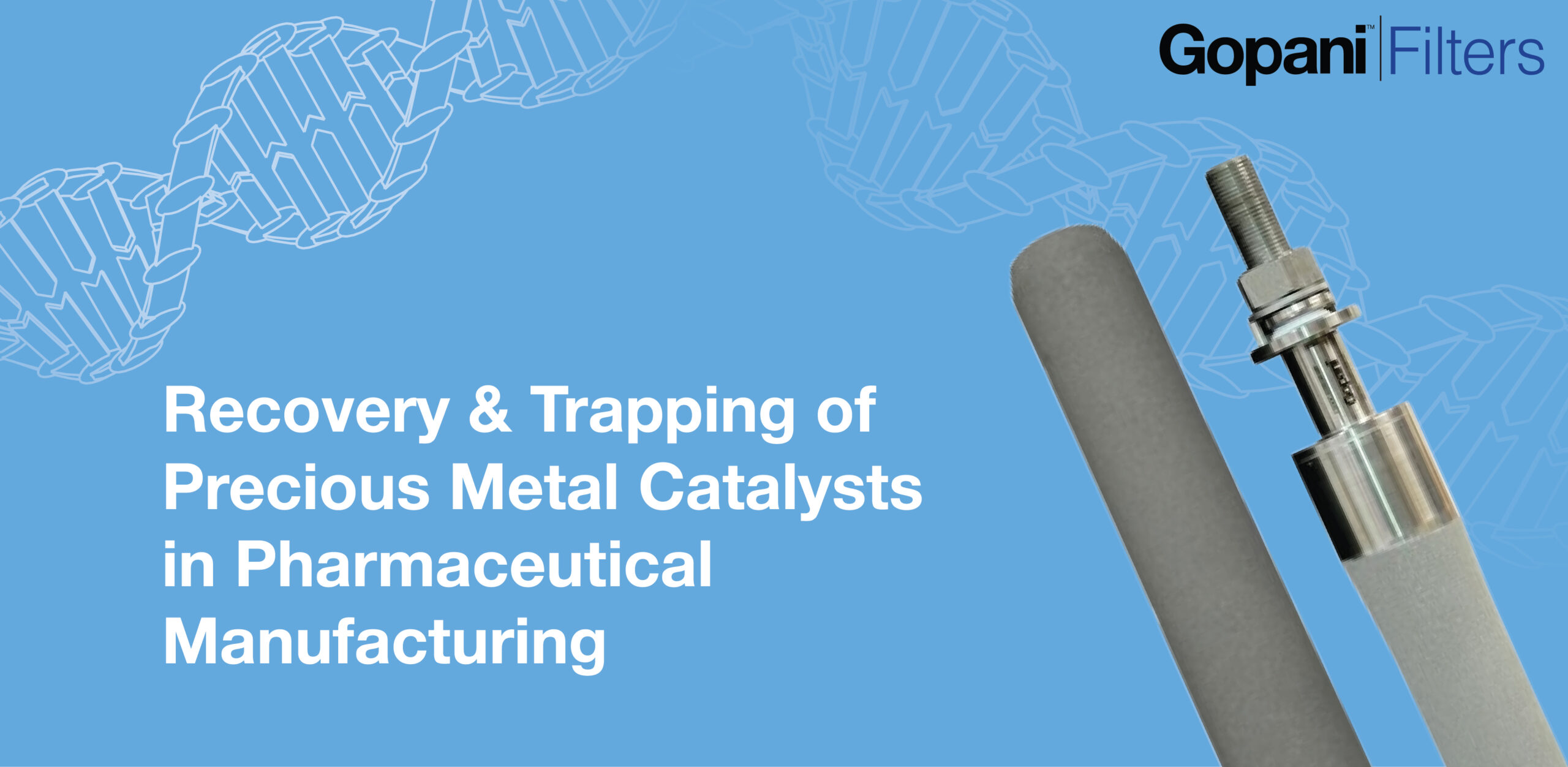

Catalyst Recovery and Recycling

Catalyst recovery and recycling is a key aspect of Sustainable Manufacturing and Green Chemistry. In processes involving precious metal catalysts like Platinum, Rhodium, and Palladium Catalysts, the use of specialized Catalyst Filters for Precious Metal Catalysts is essential. These filters not only prevent catalyst loss but also facilitate catalyst recovery, allowing for their reuse and recycling.

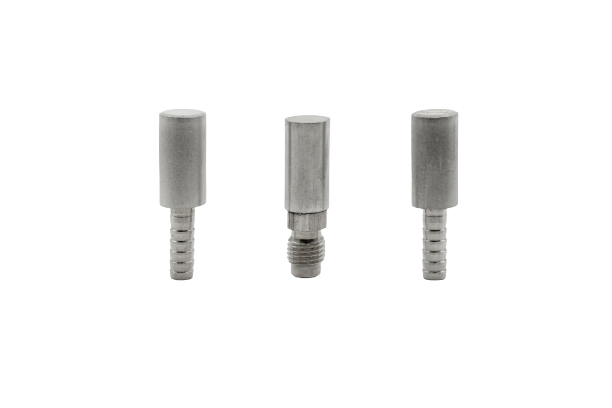

Customized Filtration Solutions

At Gopani, we understand that each industrial process, whether it’s Hydrogenation of Ethyne, Catalytic Hydrogenation, or Hydrogenation of Alkenes, is unique. Therefore, we offer Customized Sintered Filter Solutions and Custom Engineered Porous Sintered Filters, tailored to fit specific process requirements. This includes Catalyst Circulation Filtration, Batch Catalyst Filtration, Hot Catalyst Filtration, and Low Pressure Catalyst Filtration among others.

Catalyst Filter Maintenance

Maintaining the efficiency of catalyst filters involves regular cleaning, repair, and potential retrofitting. At Gopani, we offer services like Catalyst Filter Cleaning, Damaged Porous Filter Restoration, and Sintered Filter Regeneration to ensure your filters are always in optimal condition.

Ensuring Safety and Compliance

With a focus on safety, Gopani filters comply with Catalyst Filtration Safety Standards. In addition, our experts can provide consultation on Process Scale-up, Reactor Design, and Process Intensification to ensure safe and efficient operations.

The Future of Filtration

As the field of filtration evolves, new technologies like Computational Fluid Dynamics and advancements in Mass Transfer and Heat Transfer are being integrated into filter design. At Gopani, we’re constantly innovating, striving to improve our filters, and ensure they’re at the forefront of filtration technology.

In conclusion, the role of filtration in minimizing catalyst attrition cannot be overstated. By choosing high-quality filters and implementing effective filtration strategies, it’s possible to significantly reduce catalyst attrition, improving the efficiency and sustainability of industrial processes. Reach out to Gopani today to learn more about our filtration solutions and how they can help you optimize your operations.

precious metal catalysts, Platinum, hydrogenation, adium catalyst, raney nickel catalyst, hydrogenation of alkynes, catalyst recovery filter, Process Intensification, Process Scale-up, hydrogenation of alkenes, Biomass Gasification, nickel catalyst for hydrogenation, catalyst filtration, hydrogenation of oil catalyst, vanadium pentoxide catalyst, Hydrodynamic Behavior, Reactor Performance, co2 hydrogenation to methanol, Catalyst Regeneration, Cracking Catalysts, raney nickel formula, Molybdenum Catalysts, Homogeneous catalyst filtration, catalyst filtration system, raney nickel organic chemistry, Rhodium Catalysts, Catalyst Filters, precious metal catalysts recovery, Platinum Catalysts, Ammonia synthesis Catalysts, Dehydrogenation Catalysts, Fischer-Tropsch synthesis Catalysts, Nitrogen oxide reduction Catalysts, Oxidation Catalysts, catalyst trapping, Fixed Bed Reactor, Coal Combustion Filters, raney nickel catalyst sds, raney nickel catalyst specification, Automated catalyst filtration, Catalyst Coking, Catalyst Cost Efficiency with filtration, Catalyst Elutriation, Catalyst Fluidized Bed Technology, Catalyst Lifecycle Management, Catalyst Lifespan, Catalyst cake filtration, Drum Filter Manufacturers in India, Filtration of adium, High temperature catalyst filtration, Improving sintered filter efficiency, Large pore catalyst filters

Sintered Filter Elements and Systems for Tailored for Industries Like

Pharmaceuticals and API

Speciality Chemicals

Food and Beverage

Transportation

Refining and Petrochemicals

Fine Chemical

Instrumentation

Diagnostics

Standards

ISO 12500-3 in gas = Air and ASTM F795 in Liquid = Water

Types of Sintered Filter Elements

Factors to Consider before Buying a Sintered Cartridge Filter

- Operating conditions (temperature, pressure and flow rate)

- Filtration precision and filtration efficiency

- Appropriate material (corrosion resistance and high temperature resistance)

- Allowable pressure drop

- Appropriate medium strength (tensile strength, fatigue strength and load capacity)

Petrochemical Processing, Pharmaceutical Manufacturing filters, Porous sintered filter cleaning, Precious Metal Recovery Filters, Reconditioning porous sintered filters, Recovery or Filtration of noble metal catalysts, Removal of activated carbon, Reusable catalyst filter bags, Sintered metal filter manufacturing pioneers, Small batch sintered filter production, Solvent resistant catalyst filters, Welded catalyst filter cartridges, Zero Hold-up filters, catalytic hydrogenation of vegetable oil is also known as, raney nickel, Computational Fluid Dynamics, vanadium pentoxide, raney catalyst, Fluidized Bed Reactor, Waste Incineration, Ruthenium, Heterogeneous Catalysis, catalytic hydrogenation of alkenes, Reaction Kinetics, catalyst recovery filters, Hydrodesulfurization Catalysts, Multiphase Flow, hydrogenation of benzene, Bubble Dynamics, raney nickel catalyst supplier, Catalyst Deactivation, Catalyst recovery, Methanol synthesis Catalysts, explain hydrogenation of alkenes, raney nickel catalyst Filtration, Carbon catalyst filtration, raney nickel catalyst applications, raney nickel catalyst filter system, raney nickel catalyst hazards, raney nickel catalyst manufacture, raney nickel catalyst safety, raney nickel type catalyst, solid Catalyst Filter Raney Nickel, stabilized raney nickel catalyst, Bleaching earth removal in Vegetable oil plants, Catalyst Degradation, Catalyst Filter For Raney Nickel Filtration

Have Questions About Our Product ?

Drop in your Requirement Details

Talk to our representative to get insight on which product will suit you.

hydrogenation meaning, catalyst recovery, catalyst hopper, Heat Transfer, Reactor Design, catalyst filter, Transition Metal Complexes, Mass Transfer, Catalyst Attrition, hydrogenation of ethyne, Homogeneous Catalysis, Nickel Catalysts, Coal Combustion, hydrogen peroxide manganese dioxide, Environmental Catalysis, Precious Metal Catalyst Filters, raney nickel catalyst reaction, adium Catalysts, Hydrogenation Catalysts, Hydrodenitrogenation Catalysts, Reforming Catalysts, Catalyst Recovery Filtration, hydrogenation using raney nickel catalyst, raney nickel catalyst activation, raney nickel catalyst grade, raney nickel catalyst manufacturer, spent raney nickel catalyst, Acid resistant catalyst filters, Alkali resistant catalyst filters, Batch catalyst filtration, Catalyst Activity Loss, Catalyst Circulation filtration, Catalyst Filtration Safety Standards, Catalyst Sintering, Catalyst filter cleaning, Catalyst polishing filters, Catalyst separation, Catalyst slurry filtration, Catalytic Activity Filters, Ceramic catalyst filters, Cricket Filter Manufacturers in India, Customized sintered filter solutions, Disc Filter Manufacturers in India, Disposable catalyst filter bags, Hastelloy catalyst filters, Hot catalyst filtration, Improved porous tube stability, Membrane catalyst filtration, Metal nanoparticle catalyst filtration, Metallic Filter Manufacturers in India, Multi Tube Filter Manufacturers in India

Related Blogs