Gopani's Carbonation and Diffusion Stones: The Best Solution for Carbonating Beers and Beverages

What is a Diffusion Stone?

A diffusion stone, also known as a carbonation stone, is a device primarily made from porous metals like stainless steel. Often referred to as ‘Air Stones’, these devices are primarily used to aerate wort before fermentation, fostering a healthy start to the fermentation process.

Contrary to its name, a carbonation stone is not a stone but a finely sintered stainless steel component, widely recognized in the market for its durability, ease of cleaning, and longevity. It plays a crucial role in dissolving various gases such as Hydrogen, Carbon Dioxide, Chlorine, Ozone, etc., into liquids to create liquid solutions rich in these gases.

Features of Gopani’s Sintered Metal Carbonation Stone

Gopani’s metal diffusion stones are engineered to diffuse gases like oxygen or hydrogen into liquids such as water or solvents. The main features of our sintered metal carbonation stones include:

- Porous structure: Highly porous, allowing gases to seamlessly diffuse into liquids.

- High surface area: Increased surface area augments their ability to diffuse gases into liquids.

- Chemical stability: Can withstand high temperatures and pressures while maintaining stability.

- Easy to clean: Maintenance-friendly, ensuring a longer lifespan.

- Long lifespan: Can be used for many cycles before needing replacement.

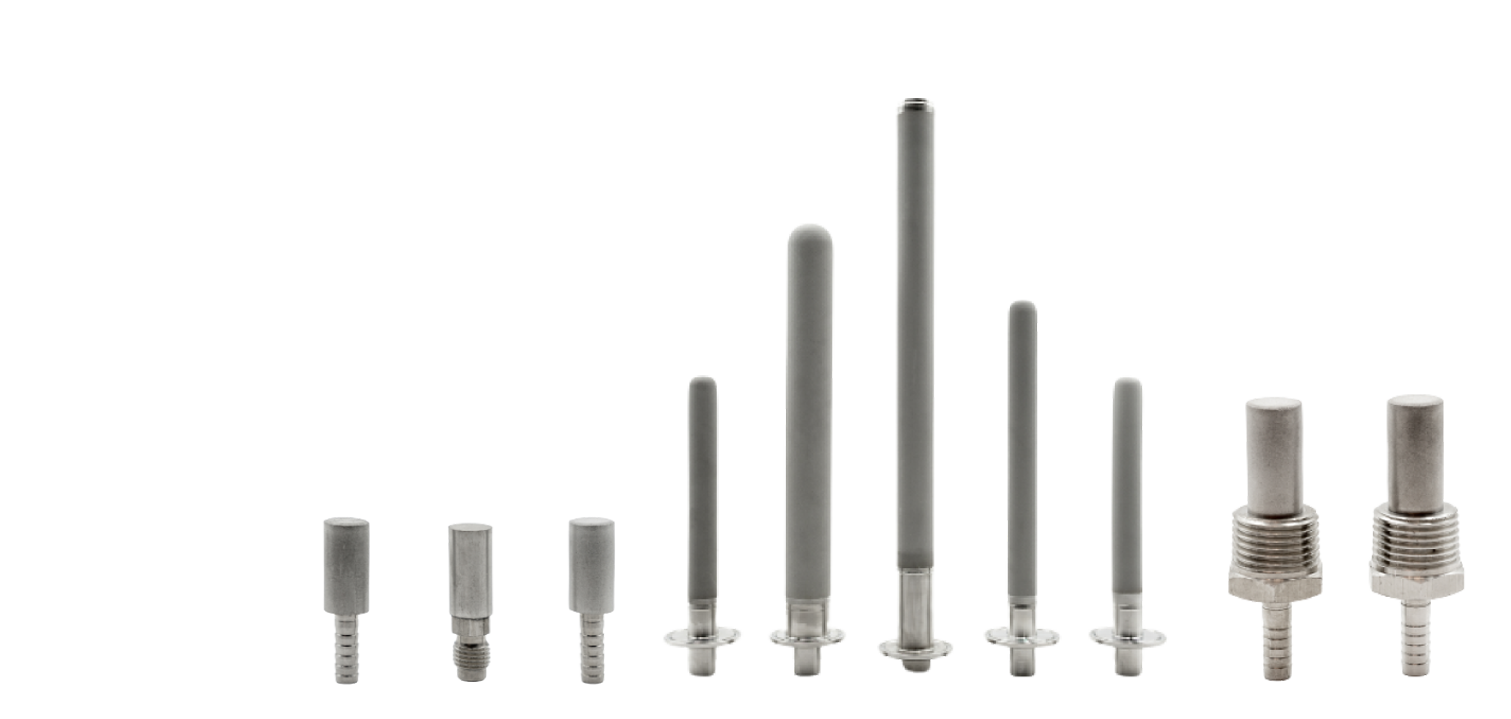

- Customization: Can be tailored to meet specific needs, such as different pore sizes or shapes.

- Versatility: Suitable for various applications, including water treatment, chemical reactions, and gas-liquid mass transfer.

- Durability: Can withstand harsh conditions, making them suitable for use in industrial settings.

Customizable Diffusion Stone

At Gopani, we understand that each application has unique requirements. We offer a full range of customization options, including:

- Size:Normal size is D1/2″\*H1-7/8“, with available pore sizes between 0.5 um – 2 um and 1/4″ Barb – 1/8” Barb.

- Materials:Available materials include Sintered Stainless steel 316L, 366, Monel, and Nickel.

- Pore Size:We offer a range of pore sizes from 0.2 – 120 um.

- Installation Ends:We offer various installation ends, including Female Thread, Flare thread, or with Wand.

- Flange Plate:We can customize diffusion stones with a Flange Plate for fixed installations.

Why Choose Gopani?

Gopani is a leading provider of Diffusion Stone for various industries, including aquaculture, hydroponics, and water treatment. With over a decade of experience in the field, we have developed a reputation for producing top-quality Diffusion Stone that meets our customer’s needs.

Our team of skilled professionals is dedicated to providing the highest level of service. We use advanced equipment and techniques in our production process to ensure that our Diffusion Stone meets the highest standards of quality and performance. We are also committed to sustainability, using environmentally-friendly materials and processes in our production.

Customer satisfaction is at the heart of our operations. We work closely with our clients to understand their needs and tailor our products to meet their specific requirements. Whether you are a business looking for a reliable supplier of Diffusion Stone or an individual seeking a partner for your project, we would be happy to discuss your needs and explore potential opportunities for working together. sales@gopani.com today to learn more about what we can offer.

Talk to US

FAQs: Gopani Carbonation/Diffusion Stone

1. What is a diffusion stone and how does it work?

A diffusion stone is a porous device used to introduce gases into liquids. It is commonly used in brewing and fermentation processes to oxygenate wort or introduce carbon dioxide to beer. The stone releases tiny bubbles of gas into the liquid, which then disperse and dissolve evenly.

2. How do I use a Gopani carbonation stone to carbonate my beer?

You will need a container to hold the beer, a CO2 tank, and a regulator. Ensure your container and carbonation stone are clean and sanitized. Attach the CO2 tank and regulator to the container, set the pressure to the desired level, and connect the stone to the gas inlet. Allow the gas to flow through the stone and into the beer. After a few days, the beer should be fully carbonated.

3. Can I use a carbonation stone to carbonate other beverages?

Yes, a carbonation stone can be used to carbonate a variety of beverages, not just beer. The process is similar, but pressure and carbonation time may need to be adjusted based on the specific beverage and desired level of carbonation.

4. How does a Gopani carbonation stone compare to others on the market?

Gopani carbonation stones are made of high-quality stainless steel, which is durable and resistant to corrosion. They are designed to perform optimally, ensuring even distribution of gas throughout your beverage.

5. How do I properly clean and sanitize my Gopani carbonation stone?

First, remove the stone from your container and rinse it with hot water. Then, soak it in a solution of hot water and a brewing sanitizer. Allow it to soak for a few minutes, then rinse it again. It’s important to clean and sanitize the stone every time you use it to prevent contamination.

6. Can I use an inline carbonation stone in my keg system?

Yes, inline carbonation stones can be used in a keg system. Connect it directly to the gas line supplying pressurized gas to the keg. The stone will release small bubbles of gas into the beer as it flows through the keg, allowing for even carbonation.

7. Is a stainless steel carbonation stone better than a plastic one?

Stainless steel carbonation stones are generally more durable and resistant to corrosion than plastic ones. They can also withstand high temperatures and are easier to clean and sanitize.

8. Can I use a stainless steel aeration stone to oxygenate my wort during brewing?

Yes, a stainless steel aeration stone can be used to oxygenate your wort during brewing. The stone releases small bubbles of air into the wort, promoting healthy yeast growth and fermentation.

9. Why might I use a 2-micron diffusion stone?

2-micron diffusion stone releases very small bubbles of gas, which can be beneficial when a high level of oxygenation is required, such as in mead or cider production. It can also be used to add carbon dioxide to beverages in a controlled manner.

10. How do I install a Gopani carbonation stone in my fermenter or keg?

Attach the clean and sanitized stone to the gas inlet using a gas line. If you are using a keg, you may also need to attach the stone to the gas line leading to the keg.

11. Can I use a carbonation stone to force carbonate my beer?

Yes, you can force carbonate your beer using a carbonation stone. However, you will need a source of pressurized gas other than CO2. The choice of gas may affect the taste and appearance of the beer.

12. How do I know when to replace my Gopani carbonation stone?

Replace your carbonation stone every 6-12 months, or whenever it becomes damaged or clogged. Signs that it might be time to replace your stone include decreased performance, difficulty maintaining proper carbonation levels, or visible signs of damage or wear.

13. Can I carbonate hard cider or non-alcoholic beverages with a carbonation stone?

Yes, you can use a carbonation stone to carbonate hard cider or other non-alcoholic beverages. The process is similar to carbonating beer, but pressure and carbonation time may need to be adjusted based on the specific beverage.

14. How do I properly store my Gopani carbonation stone when not in use?

After cleaning and sanitizing the stone, allow it to dry completely before storing it. Store the stone in a dry, airtight container or bag to protect it from moisture and contaminants.

15. Is it safe to use a carbonation stone with food-grade CO2?

Yes, it is safe to use a carbonation stone with food-grade CO2. However, it is important to follow safety guidelines when handling CO2, such as wearing protective gear and avoidingprolonged direct contact with the skin.

16. What’s the difference between a 0.5 micron and a 2 micron carbonation stone?

The difference between a 0.5 micron and a 2 micron carbonation stone lies in the size of the pores on the stone, which affects the size of the gas bubbles released. A 0.5 micron carbonation stone releases smaller bubbles, which can dissolve into the liquid more efficiently, while a 2 micron stone releases slightly larger bubbles.

17. Can I use a Gopani carbonation stone to oxygenate my aquarium?

While a Gopani carbonation stone is designed for brewing and carbonation purposes, it could technically also be used to oxygenate an aquarium. However, it’s crucial to ensure that the stone is thoroughly cleaned and sanitized before use and that the gas being used is safe for aquatic life.

18. How do I decide the right PSI setting for carbonating my beverage?

Choosing the right PSI setting for carbonating your beverage depends on several factors, including the type of beverage, the desired level of carbonation, the temperature of the beverage, and the specific instructions provided with your carbonation stone. Generally, the PSI setting for carbonating beer is between 10-30 PSI, but you may need to adjust this depending on your specific circumstances.

19. How often should I clean my Gopani carbonation stone?

It’s recommended to clean your Gopani carbonation stone after each use to ensure it remains free of contaminants. Regular cleaning helps maintain the stone’s performance and extends its lifespan.

20. How long does it take to carbonate a beverage with a Gopani carbonation stone?

The time it takes to carbonate a beverage with a Gopani carbonation stone can vary depending on several factors, including the type of beverage, the desired level of carbonation, the temperature of the beverage, and the PSI setting on your CO2 tank. However, it typically takes between 1 to 3 days to fully carbonate a beverage.